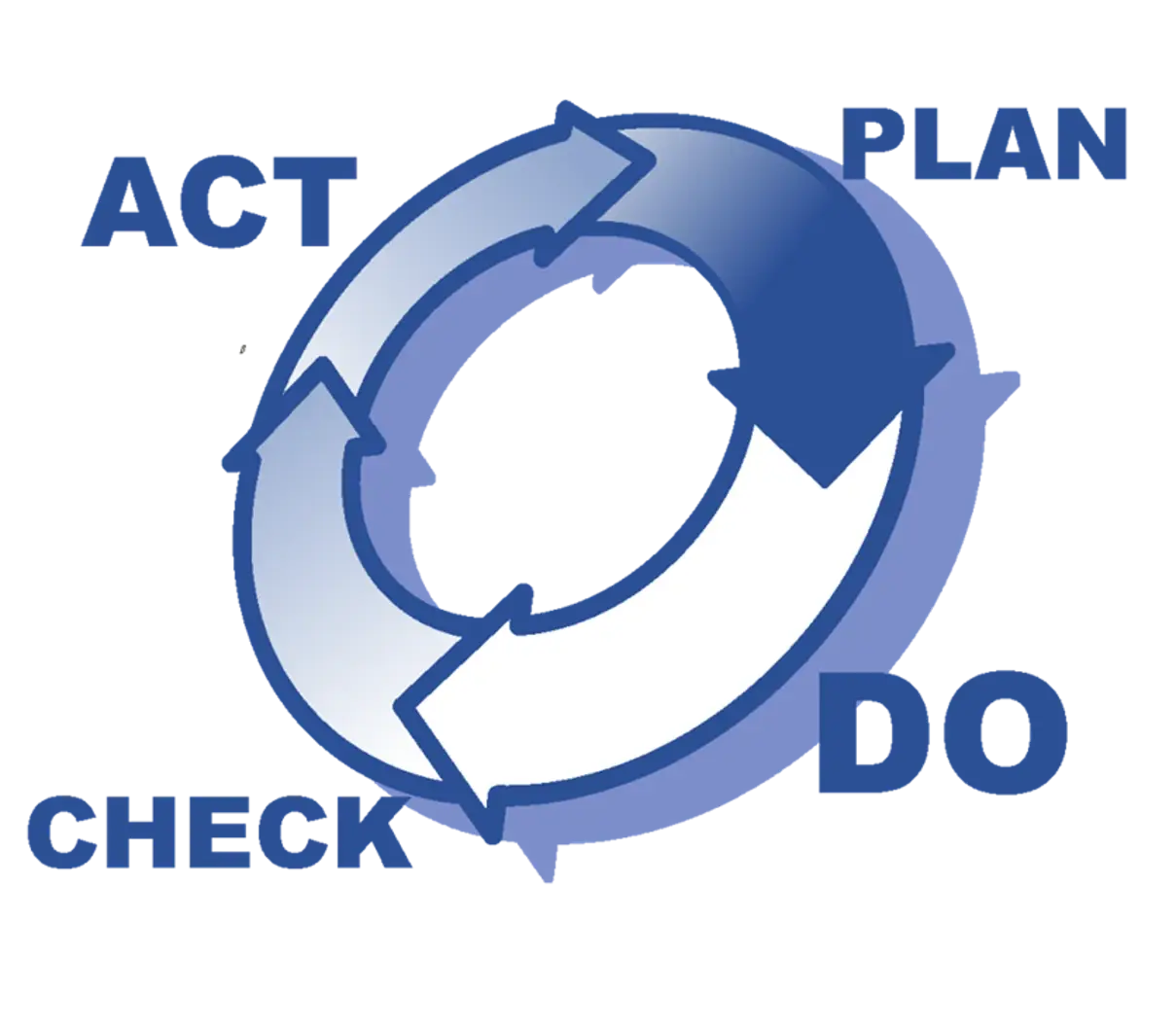

Plan, Do, Check, Act is a more updated version of the original Health and Safety Executive (HSE) POPIMAR, or Policy, Organising, Planning, Implementing, Measuring performance, Auditing and Review model. An excellent article on the RoSPA website details the changes between the two systems. Part of the aim of the IOSH was to make the health and safety aspects of a business integral to everyday operations as opposed to a standalone element. You may not be aware, but the original HSE POPIMAR model was contained in a 100-page document, so you can perhaps understand why health and safety were seen as separate elements to a business's day-to-day running.

However, it should be noted that while one of the goals of Plan, Do, Check, Act is to make health and safety integral to running a business, it remains an important topic and one of Commodious’ most substantial courses. So, let us look at the purpose of Plan, Do, Check, Act and then we will take a closer look at the individual elements.

What is different with Plan, Do, Check, Act compared to POPIMAR?

One of the key elements of health and safety in the workplace is its use in introducing new working practices. However, Plan, Do, Check, Act, or PDCA, can be applied to all changes introduced to a business.

POPIMAR | PDCA |

Systems and process orientated | More emphasis on behavioural aspects |

Health and safety positioned as a separate business function | Health and safety management an integral part of good management generally |

A detailed 100+ page manual | A microsite providing an overview with links to further details |

Provides detailed coverage of the key elements of a health and safety management system using POPIMAR:- Policies- Organising- Planning- Implementing- Measurement- Audit- Review | Advocates a revised approach to putting health and safety arrangements in place or for overseeing them:- Plan, Do, Check, Act. |

The table shows the principal differences between POPIMAR and PDCA. You will immediately see where one of the major problems with POPIMAR has been resolved: the change between a 100-page manual and a microsite that provides easy access to pertinent information.

What is the ‘Plan’ part of Plan, Do, Check, Act?

Implementing Plan, Do, Check, Act presupposes that you have already identified the problem you wish to fix, or area of operations where you feel there could be improvements made to the health and safety elements. It should also be noted that the plan element is not a general and widespread philosophy but must relate to a specific element of the business. The beauty of Plan, Do, Check, Act is a process that bears repeating for every element of the business where you are looking to make changes.

There are four main elements to the ‘Do’ part:

- First, it is important to establish where you are and where you want to be. In other words, it is important to make a full assessment of the current situation regarding a particular health and safety element of the business and, more importantly, clearly identify where you want to be in the future. There is little point in identifying where an improvement can be made without indicating where you want to be once the change has been made.

- Closely connected with the first element is identifying exactly what you want to achieve through any specific change. Once again, there is little point in identifying an area for improvement if you can’t determine what the tangible benefits will be. At this stage, it is also important to clearly identify who will be responsible for implementing the planned change or changes.

- Sometimes, the effects of change can’t either be easily seen or become immediately visible. Consequently, it makes sense to put in place a system specifically designed to measure the level of performance in any policy change. Failure to do so will make it next to impossible to assess the success of any change.

- Expect the unexpected. Rarely do any plans go exactly as hoped, and the unexpected can always happen in any working environment. With the implementation of any change, contingencies should be put in place that will mitigate the effects of any deviation from anticipated outcomes. As the old adage goes: “Fail to plan, plan to fail.” Depending on the changes themselves, it may also pay to check the legal implications of any change.

What is the ‘Do’ part of Plan, Do, Check, Act?

It should be no surprise to learn that the ‘Do’ element relates to putting plans into action. However, before that can be done, other matters need to be attended to. Because of the critical nature of implementing any change, it is vital that every contingency is in place. So, the ‘Do’ part will usually contain three elements:

- First, identify your risk profile. This can be done by identifying what, in the workplace, could cause any harm, plus how and what you will do to manage that risk. The biggest risks should be clearly identified, and priorities decided upon. An excellent article titled Managing risks and risk assessment at work issued by the HSE provides a clear explanation of what is involved. Additionally, you may want to consider ensuring that all managers have taken the Commodious Online Risk Assessment Training Course as this will help implement a PDCA system.

- Second, you should organise what should be done to instigate any planned changes. This will likely involve engaging with workers through clear communication to improve engagement levels and positive attitudes and behaviours. Everyone must have access to competent advice where it is felt it will be needed.

- Lastly comes the implementation of your plan. You should decide on what preventative and protective measures must be implemented. It is also important to ensure that the right tools have been provided for the task at hand. Staff needs to be trained/retrained in order to enact change, while staff should also be supervised to assist with any such changes and to ensure they are implemented correctly.

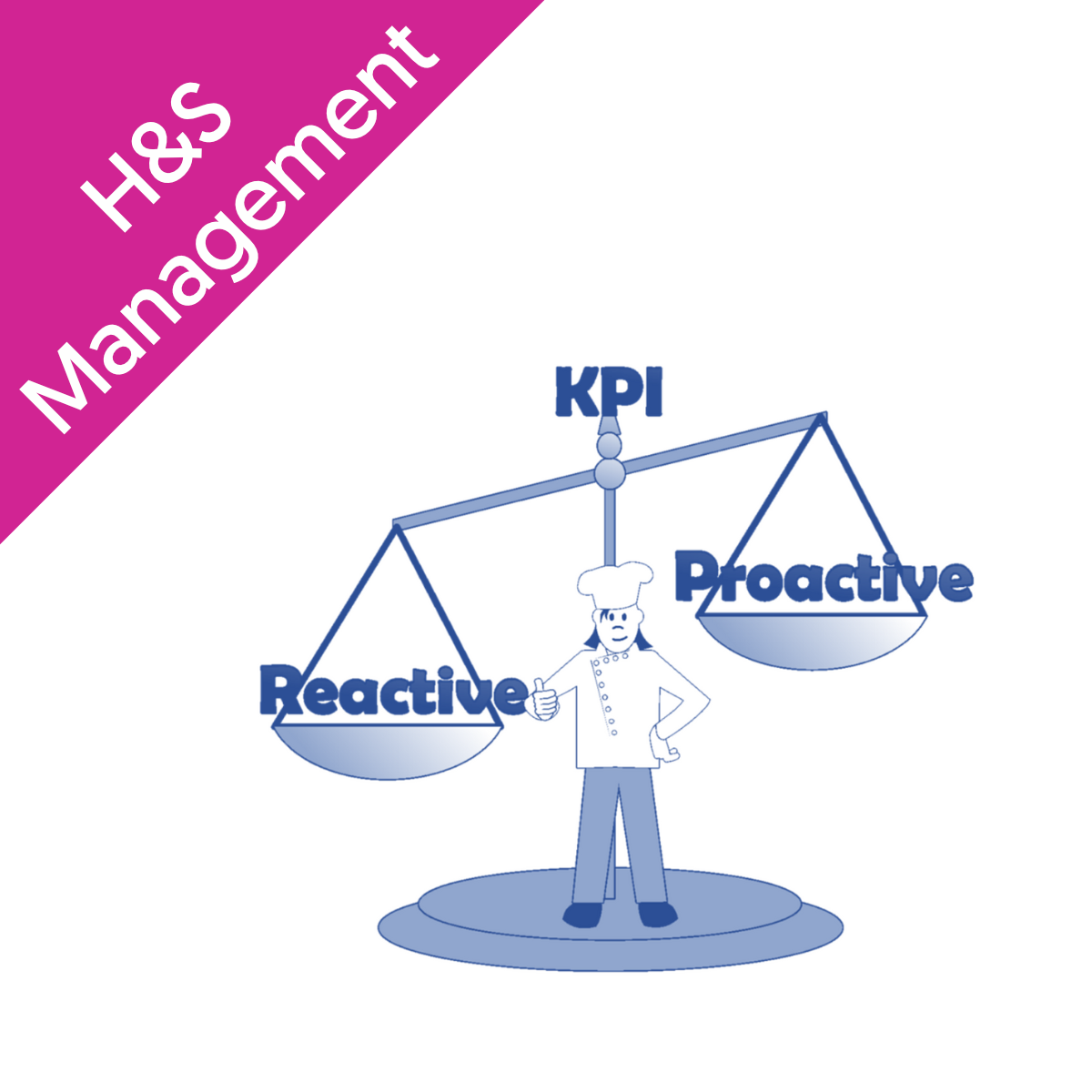

What is the ‘Check’ part of Plan, Do, Check, Act?

There is little point in implementing change if you don’t check to see whether or not the change has had a positive outcome, if there are any tangible benefits. Simply implementing change and moving forward with other plans could ultimately prove counterproductive if you don’t measure how effective the changes made have been. There are two main elements to the ‘Check’ part of PDCA:

- First, measure performance. Assuming that changes will achieve the desired results is naïve and too presumptuous. Part of the ‘Check’ part is to make sure that all the staff has understood alterations to working procedures and that they have been fully implemented. Since change has been implemented to minimise certain risk(s), you need to check that you have successfully achieved this, which may involve a formal audit.

- The second vital aspect of ‘Check’ is further to investigate the causes of any accidents, incidents, and also very important, near misses, if there have been any. Implementing a Plan, Do, Check, Act policy is to reduce the likelihood of an accident occurring in the workplace. However, one can only instigate measures, there is no escaping the fact that accidents may and will still happen, often through wholly unavoidable circumstances. If there was a way of eliminating all accidents, there would be no need for so many insurance companies!

What is the ‘Act’ part of Plan, Do, Check, Act?

One of the many benefits of a Plan, Do, Check, Act policy towards health and safety n the workplace is that it is predominantly proactive instead of reactive. By this, we mean that you are targeting the avoidance of accidents before they happen, as opposed to implementing new policies once an accident has happened. However, it is important to understand that implementing the policy is one thing, ensuring that it is successful is another. That is where the ‘Act ‘ element comes to the fore.

By ‘Act’, we mean review what has happened since you implemented any new working practices. Analyse and learn further from any accidents or incidents, check employee health data, and don’t be afraid to see what is happening with other firms operating in the same field.

It will always pay to revisit plans, policy documents and risk assessments to see if they all still hold up or if further modifications are required. The best policy is to take action based on lessons learned, particularly from any audits or inspection reports.

The concept of Plan, Do, Check, Act may be new to you and one of the questions you may now have is how to deliver effective arrangements for health and safety at work. The government's Health and Safety Executive (HSE) have published excellent guidance on the subject here.

Here at Commodious we specialise in providing online courses that cover many aspects of Health & Safety at work. If you would like to learn more about any of these, please feel free to get in contact with us.