How do hazardous substances enter the body?

Hazardous substances can enter the body in several ways. There are four ways that dust tends to enter the body.

Breathing in dust particles

It is easy to breathe in dust particles that are floating in the air. Too much dust inhalation can lead to breathing problems including lung disease. Two types of dust can be breathed in - inhalable and respirable dust. Total inhalable dust is larger and usually gets trapped in the mouth, nose or throat, where it causes damage. Respirable particles are smaller and can build up in the lungs, leading to lung damage.

Swallowing dust particles

When dust is breathed in it can become trapped in mucus. This is usually either spat out or swallowed. When it is swallowed it can cause gastrointestinal irritation or enter the blood, which in turn allows it to cause problems elsewhere in the body.

Eye contact

Particles produced during cutting, grinding and drilling can cause eye damage and irritation. Some substances may cause eye damage due to their chemical nature.

Skin contact

Some dusts are irritating or damaging to the skin. They can cause rashes or ulceration on contact.

![diagram of the Four Ways that Dust Particles Can Enter the Body diagram of the Four Ways that Dust Particles Can Enter the Body]()

Four Ways that Dust Particles Can Enter the Body

How do I control construction dust?

Controlling construction dust is not always easy. However, limiting the amount of dust created by changing how a task is done is a good start. Some examples of how to do so include:

- Using the right size of building materials so less cutting and preparation is required.

- Using less powerful tools. For example, a block splitter could be used instead of a cut-off saw.

- Using alternative work methods. For example, nail guns can be used with wood to avoid having to drill holes.

Some work that creates a lot of dust is inevitable. In these situations, a suppression system or an extraction system should be used to stop or limit the amount of dust that gets into the air:

- Water suppression systems: Water suppression systems use a constant flow of water to dampen particles and stop them from becoming airborne. The flow of water needs to be sufficient - damping down an area before beginning work will not be enough to reduce the amount of airborne particles.

- Local exhaust ventilation (LEV): LEV systems can be attached to hand-held or static tools to remove the dust they create and take it elsewhere for filtration or disposal.

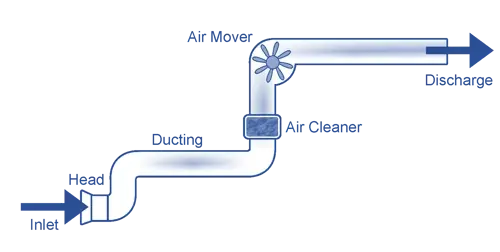

What is LEV?

Local exhaust ventilation (LEV) is a dust extraction system used to reduce dust exposure in the workplace. As the name implies, an LEV system is installed at the source of the dust to remove it before it can cause harm.

LEV extraction combines two key systems: an air extraction system and an air filtration system. It is usually installed where stationary tools, such as pedestal grinders, are in use.

The diagram below shows the key elements of an LEV system:

![LEV system diagram LEV system diagram]()

LEV systems must be correctly installed, ideally by a trained professional, so that they can effectively act as a dust prevention measure.

How to reduce dust when grinding concrete

Grinding concrete releases respirable crystalline silica (silica dust) into the air. Find out about the danger of silica dust here.

A dust suppression system that is commonly employed when working with concrete uses water to stop particles from becoming airborne. There are two types of this system: a water suppression bottle system and a mains water system. The first uses a dust-suppression water bottle and is more portable than the other which relies on a mains water supply.

Why is PPE important?

Personal protective equipment, or PPE, is the last line of defence against hazardous substances in the workplace. The importance of PPE in the workplace cannot be understated.

When other dust control measures do not reduce exposure to a satisfactory level, PPE and RPE (respiratory protective equipment) must be employed.

PPE may include disposable coveralls to protect personal clothing and skin, eye protection, or a full face dust mask to offer respiratory protection. Some PPE to protect workers from dust include:

- face coverings, such as moulded disposable face masks

- half mask respirator

- disposable workwear

When using a mask, it is important to ensure a good fit to improve the protection level. Face fit testing helps in determining if the seal of the respirator is secure enough to prevent dust from entering. It is important to note that a respirator relying on a face fit would not be effective if there is a beard or thick beard stubble, as it may cause leaks around the seal. Therefore, undergoing a fit test is crucial for ensuring optimal dust control and safety in hazardous environments.

In short, PPE helps to prevent too much dust inhalation, skin contact and eye contact.

Are members of the public at risk from breathing in construction dust?

No, the harm that construction dust inhalation causes usually develops over a long period when a person is repeatedly and regularly exposed. That said, breathing in the dust even for a short period is unpleasant, and can cause a reaction in people with asthma or other respiratory problems.

Adequate measures of dust control should always be taken and members of the public should be kept away from work that creates dust.

Where can I get more information about dust and other risks to my lungs?

This article offers an in-depth guide to respirable crystalline silica, and the HSE offers guidance on how to control hazardous substances here.

You can find further information and guidance on the dangers of dust and how to control dust in the workplace in our Dust Awareness Online Training Course: